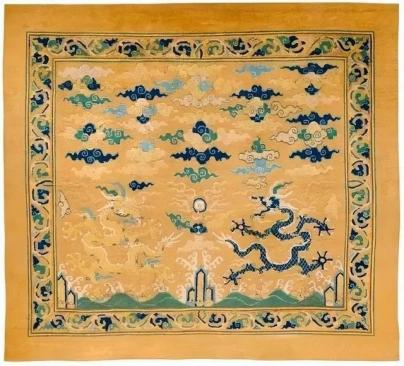

Throughout history, carpets have been more than mere floor coverings—they have been symbols of power and luxury. On November 23, 2021, a carpet that once adorned the Golden Hall of the Forbidden City was auctioned at Christie's in Paris for 6.88 million euros. This carpet, woven in the sixteenth century during the Ming Dynasty, originally a vibrant imperial red, has now faded to a golden hue, measuring approximately 5×4 meters. It has not only witnessed the splendor of Chinese royalty but also represents the pinnacle of traditional Chinese carpet craftsmanship.

At the center of the carpet is an embroidered pearl, flanked by two five - clawed dragons, symbolizing the emperor's supreme position. The carpet's surface features not only dragons but also ascending auspicious clouds, depicted with simple lines to convey the sense of rising and good fortune, showcasing the exquisite Eastern charm. After centuries, the knots on the back of this carpet remain tight, with no signs of loosening.

Ningxia carpets, known as the "official kiln" of carpets, were highly favored by the royal family during the Qing Dynasty. Their superior quality stems from several advantages. Firstly, Ningxia's location in Northwest China provides excellent natural conditions. The wool from the Mongolian native sheep raised there is long - fibered, elastic, lustrous, and has a high pile density, making the carpets, known as "pile carpets," of superior quality. Secondly, Ningxia carpets are made using traditional hand - knotting techniques, with the pile knotted in an "∞" shape, commonly known as the 8 - character knot. The weaving density is high, with 11 - 15 knots per 5 centimeters and a thickness of about 5 - 8 millimeters, resulting in a soft texture and strong warmth retention. Moreover, Ningxia carpets integrate the traditional weaving skills of various ethnic groups in the Northwest. Their patterns incorporate elements from Uyghur geometric patterns, Han brocade and embroidery, dragon and phoenix motifs, as well as Tibetan Buddhist "Eight Treasures" and "Eight Auspicious Symbols," creating a unique artistic style. Additionally, Ningxia carpets were designated by the Qing government as temple - exclusive carpets and served as tribute and gift carpets, with patterns and colors that met the royal aesthetic standards, reflecting high artistic and cultural value.

FULI Carpets: A Perfect Blend of Heritage and Innovation

FULI Carpets, with their exquisite craftsmanship and relentless pursuit of detail, continue the tradition of royal carpet luxury. At the January 2025 Paris "Maison & Objet" home decor fair, FULI showcased its high - end carpets under the theme "Weaving Dreams." These carpets, made from top - grade wool, silk, and other materials, combined traditional techniques such as hand - tufting, cut - pile, and loop - pile, presenting a rich visual texture.

The production process of FULI carpets is a testament to the传承与创新 of traditional craftsmanship. Craftsmen skillfully combine cut - pile and loop - pile techniques to create carpets that are both soft to the touch and structurally tight. Additionally, FULI has introduced eco - friendly materials such as ECONYL® and polyolefins, which are not only durable but also reduce dependence on natural resources.

Supply Chain Strength: Global Top - Tier Materials and Cutting - Edge Craftsmanship

The supply chain strength of FULI Carpets is a solid guarantee of its high - end quality. FULI selects premium materials such as high - grade wool from New Zealand and Australia, as well as rare and luxurious materials like silk, vegetable silk, linen, crystals, gems, gold and silver threads, and South African mohair. Moreover, FULI is committed to environmental protection and sustainable development, using eco - friendly materials like ECONYL and polyolefins, which are not only durable but also reduce dependence on natural resources.

Factory Overview

Basic Information

Location : Based in Foshan, Guangdong.

Employee Scale : With over a thousand employees.

Production Capacity : Generally, it takes about 30 - 60 working days to produce a custom - made carpet measuring 2 meters by 3 meters. The factory's monthly output can reach around 4,000 square meters, efficiently meeting customer needs. The factory accepts orders from all over the world and is capable of customizing according to individual customer requirements.

_20250507164926A003.jpg)

Operation

Production Time : The factory's production schedule is flexible.

Equipment Renewal: The factory regularly (monthly) updates and maintains its equipment

_20250507164951A004.jpg)

Supply Chain Management

FULI's supply chain management is holistic and integrated, seamlessly combining raw material procurement, production, logistics, and sales to achieve efficient collaboration across the entire chain. We are customer - centric, rapidly responding to needs and ensuring real - time information sharing through transparent systems to enhance decision - making efficiency. We also embrace a new inventory concept, optimizing stock levels through strategic partnerships with upstream and downstream enterprises to reduce operational costs. Continuous improvement and innovation are at the core of our approach, leveraging advanced technologies to constantly refine processes and boost supply chain transparency and efficiency. This comprehensive management model not only ensures high - quality product delivery but also provides an exceptional customer experience, solidifying FULI's leading position in the industry.

FULI's supply chain management views all node enterprises as a cohesive whole, spanning the entire supply chain process, including logistics, information flow, capital flow, business processes, and value creation. This approach necessitates information sharing, risk - sharing, and mutual benefits among node enterprises, emphasizing the strategic importance of supply chain management.

FULI adopts an integrated management philosophy, bringing together suppliers, manufacturers, distributors, retailers, and end - customers for comprehensive, full - process integration. This model underscores cooperation among enterprises to achieve overall optimization and enhance the entire supply chain's efficiency.

FULI's supply chain management is customer - oriented, ensuring that products reach the right place at the right time, in the right quantities, and with the right quality and condition, thereby maximizing customer value.

FULI's supply chain management has transformed traditional inventory concepts by establishing strategic partnerships with upstream and downstream enterprises to optimize and transfer inventory, reducing inventory costs.

FULI emphasizes rapid response to customer needs, utilizing advanced information systems to achieve transparency across the supply chain, thereby improving decision - making efficiency and reducing inventory buildup and missed market opportunities.

FULI's supply chain management focuses on continuous improvement and innovation, optimizing business processes and adopting new technologies (such as the Internet of Things and big data) to enhance supply chain transparency and efficiency.

FULI's supply chain management is a customer - oriented, integrated management strategy that consolidates logistics, information flow, and capital flow within the supply chain to achieve efficient collaboration from raw material procurement to product delivery, maximizing customer value and optimizing supply chain costs.

Technology and Craftsmanship

1. Technological Advantages

The company has delved deeply into tufting gun technology, with its self - developed 1600 - needle tufting gun excelling in speed, stability, and expressive power.

In terms of environmental protection, FULI Carpet has established a new internal production code. It advocates the use of natural and eco - friendly materials, strictly selects and tracks the sources of each raw material, and progressively reforms internal production processes, rigorously standardizing post - processing and final inspection procedures. Inspection checkpoints are set up at each processing stage to achieve a closed loop in material utilization, eliminating production pollution and waste, and setting an example of social responsibility for 21st - century carpet - making enterprises.

2. AI Design Process

Customers can generate their preferred patterns using the FULI + AI generation tool. After placing an order on the platform, the design can be directly sent to the printing factory for production. This realizes the synergy of user creativity, platform interconnection, and factory - made intelligence, enabling one - click printing carpet orders.

Differences Between Hand - Made and Machine - Made Carpets

·Production Process

Hand - tufted Carpets : Using manual tufting guns or hand - knotting tools, the yarn is "stabbed" into the pre - stretched base fabric. After designing the pattern, the tufting gun is manually operated to fill the yarn row by row. Once completed, glue is applied to the back to fix it in place, followed by sewing on the backing.

Machine - Made Carpets: Produced by automated tufting or weaving machines, with computer - controlled patterns and yarn density. The production speed is fast, and the consistency is high, suitable for standardized needs. However, complex patterns or high - density designs may be limited by machine precision.

·Materials

Hand - tufted Carpets : Often made from natural materials such as wool, cotton yarn, and jute, with some high - end products incorporating silk. The backing is typically natural latex or cotton fabric.

Machine - Made Carpets : Predominantly made from synthetic fibers like nylon, polyester, and polypropylene (PP), which are cost - effective and stain - resistant. The backing is mostly synthetic latex or plastic coating.

·Appearance and Design

Hand - tufted Carpets: Feature rich pattern details, capable of presenting complex hand - painted styles, gradient colors, or abstract designs. The pile height and density can be flexibly adjusted for a stronger sense of layering. Each carpet may have slight differences, reflecting the warmth of handcrafting.

Machine - Made Carpets : Often feature geometric, repetitive patterns, or simple color blocks with high pattern detail precision but lack a sense of vitality. Products from the same batch are almost identical, suitable for a uniform style in commercial spaces.

·Price and Production Cycle

Hand - tufted Carpets : High - priced due to labor - intensive production (1 square meter may take several days), high material costs, and higher customization fees. The design to completion process may take several weeks or even months.

Machine - Made Carpets : Low - priced, with large - scale production reducing unit costs, typically one - third or even lower than hand - tufted carpets. Large - batch orders can be completed in just a few days.

·Durability and Maintenance

Hand - tufted Carpets: Made from natural wool, which is wear - resistant and anti static, with a lifespan of several decades (with proper care). They require regular professional cleaning to avoid moisture and insect damage.

Machine - Made Carpets: Made from synthetic fibers that are stain - and water - resistant but can become flattened with long - term use, with a typical lifespan of 5 - 10 years. Daily vacuuming is sufficient for cleaning.

Quality Assurance

The factory strictly controls product quality with the participation of third - party inspection agencies.

Products and Services

·Material Selection: High - grade wool from New Zealand and Australia is the main material, along with a variety of high - end and rare materials such as silk, vegetable silk, linen, crystals, gems, gold and silver threads, and South African mohair.

·Customization Services:Size and Shape Customization: Customers can customize the size and shape of carpets without any size restrictions.

·Installation Services : FULI brand offers installation services with fees based on the actual product.

Customer Relationship:

·Special Needs Processing: If customers have special design or functional requirements, FULI designers will take the lead in。

·Customer Groups: Main customers include individual consumers, commercial clients, and designers.

·Customer Feedback Handling: The factory has a dedicated customer service team to handle after - sale issues.

Future and Innovation

Development Plan : As a leading brand in the high - end carpet industry, FULI Carpet is committed to combining traditional craftsmanship with modern technology to provide consumers worldwide with exceptional products and services. The following are the future plans for FULI high - end carpets, covering multiple aspects such as technological innovation, market expansion, sustainable development, and cooperation.

1. Technological Innovation and Intelligent Manufacturing

AI Design and Intelligent Manufacturing: Empowered by AI technology, the carpet manufacturing industry is entering a new era of intelligence. Currently, with AI - based design technology, users can place orders for customized printed carpets with just one click. In the future, this technology will achieve full - process intelligence from user creativity stimulation to finished product delivery. Specifically, users can generate unique carpet designs using AI technology on the creative platform, which will then be seamlessly integrated into the factory's intelligent manufacturing system to achieve synergy between the three ends. From the birth of inspiration to the final product delivery, the entire process will be more efficient and personalized, completely reshaping the future of carpet manufacturing.

Digital Printing and Customization: By utilizing digital printing technology, FULI will be able to quickly generate complex patterns and customized designs to meet consumers' needs for unique designs.

ntegration of Intelligent Functions : In the future, FULI plans to integrate intelligent functions into carpets, such as temperature regulation and people - flow monitoring, to enhance the functionality and user experience of the products.

2. Market Expansion and Global Layout

High - End Market Positioning: FULI will continue to focus on the high - end residential and commercial markets, providing customized and high - quality carpet products. The growing demand for unique designs and high - quality materials among affluent consumers provides a broad market space for FULI.

Emerging Market Development : With the acceleration of urbanization and the expansion of the middle - class, the demand for high - end carpets in emerging markets such as the Asia - Pacific region is growing significantly. FULI plans to increase market investment in these regions and expand sales channels.

Industry Cooperation and Crossover: FULI will cooperate with independent designers, design studios, brand home producers, soft - home companies, automobile, yacht, and aircraft manufacturers in multiple fields to jointly create high - end customized products.

Industry Cooperation: As a high - end custom carpet brand, FULI has always been committed to cooperating with elites from all walks of life to perfectly combine traditional craftsmanship with modern design, providing global consumers with unique aesthetic experiences. The following are FULI's cooperation expansions in different fields:

Independent Designers: FULI closely cooperates with numerous independent designers, providing comprehensive support from creative design to finished product delivery. Through FULI's platform, designers can transform their unique design concepts into actual products, meeting consumers' needs for personalized home decoration. For example, FULI cooperated with Chinese - American artist Juju Wang, incorporating the inspiration she extracted from traditional culture and nature into carpet design to create collectible artworks.

Design Studios : FULI collaborates with design studios to explore the possibilities of innovative design. These studios, with their professional design capabilities and creative concepts, inject new vitality into FULI's products. The cooperation covers the entire process from preliminary design to final product, ensuring that each carpet meets the highest aesthetic standards.

Brand Home Producers : FULI partners with brand home producers, integrating carpets as part of an overall home solution to enhance the overall beauty and comfort of home spaces. Through cooperation with these brands, FULI can perfectly match carpet designs with furniture, decorations, and other home elements, creating a one - stop home shopping experience for consumers.

Soft - Home Companies: FULI collaborates with soft - home companies, focusing on the overall effect of interior decoration. By providing customized carpet services, FULI can meet the high requirements of soft - home companies for details and quality, jointly creating interior spaces with personality and artistic sense. This cooperation not only increases the added value of the products but also provides consumers with more choices.

Automobiles and Yachts : FULI has also expanded its cooperation to the field of high - end transportation, working with automobile and yacht manufacturers to customize exclusive carpets for these high - end products. These carpets not only have excellent quality and design sense but also perfectly blend with the interior style of automobiles or yachts, enhancing the overall sense of luxury and comfort.

3. Sustainable Development and Eco - friendly Materials

Application of Eco - friendly Materials: FULI will increase the research and application of eco - friendly materials, such as natural wool and recycled fibers, to meet consumers' attention to sustainable products.

Latex - Free Eco - friendly Technology : FULI is developing latex - free eco - friendly carpet production technology, using special thermoplastic adhesive materials and in - situ implantation technology to achieve large - scale production of eco - friendly carpets.

_20250507165124A006.jpg)

4. Product Diversification and Personalization

High - End Customization Services: FULI will offer a wider range of customization options, including patterns, colors, textures, and sizes, to meet consumers' pursuit of personalization and high - quality living.

Functional Carpets: Develop carpets with special functions such as antibacterial, stain - resistant, and self - cleaning properties to meet the needs of different commercial spaces and home environments.

5. Brand Building and Customer Service:

Brand Promotion : Enhance brand awareness and market influence through high - end retail channels and exclusive partnership relationships.

Customer Service Optimization** : Establish a professional customer service team to provide comprehensive services from design consultation to after - sale maintenance, ensuring customer satisfaction.

From Royal to Modern Living: The Art of FULI Carpets

FULI Carpets not only pursue excellence in craftsmanship but also continuously innovate in design. The "Call Me By Your Name" modular carpets perfectly integrate traditional craftsmanship with modern aesthetics, showcasing the infinite possibilities of carpet art. Whether used in high - end residences, luxury hotels, or private yachts, FULI Carpets can add a unique artistic touch to every space.

Future Outlook

As the global focus on sustainable development grows, FULI Carpets will continue to explore the integration of eco-friendly materials and traditional craftsmanship, bringing consumers more products that combine luxury with environmental protection. As showcased at the Paris Home Decor Fair, FULI Carpets are not just a form of decoration, but an art of living.